The turning unit – CNC lathe and 4th CNC axis for KOSY

The KOSY CNC machine is expanded with the turning unit by a 4th axis (U axis). Existing machines may need to be equipped with a separate axis controller. The software nccad supports the control of the turning unit. So a manufacturing of rotational parts, forks, screws and many things more is becoming possible.

There are two versions available:

- The small turning unit KSZD1 for CNC machines of the standard series – for simple tasks and small parts

- The large turning unit KSZD2 for CNC machines with minimum clearance of 100 mm – for large parts and precision work

The motor unit is powered by a stepping motor and it is mounted to the Y table of the machine. The motor unit is connected to the interface. Now the software can perform a homogeneous rotation of the rotation axis or it can be moved to a certain position. In this position the work piece can be milled like at normal milling.

The turning unit is a 4th axis which can be involved in many composed movements (E.g. engraving round bodies, milling a spiral and others). The rotation speed can be adjusted by the software.

You will get a complete CNC lathe with the following arrangement:

The turning unit is mounted to the Y table. Motor unit and chuck are holding the work piece, the tail stock and the following center point avoid the displacement of the work piece. The milling unit with the rotating milling tool is performing the cutting.

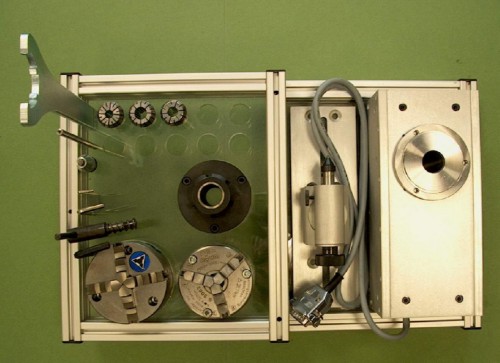

Content of delivery large turning unit:

- Turning unit with cable

- three-jaw chuck (for surcharge four-jaw chuck possible)

- tail stock with center point

- collet chuck with wrench and collets 3,0; 8,0 and 10,0 mm

- mounting accessories

Deutsch

Deutsch